Understanding the Role of Hydraulics Suppliers in Modern Business

Hydraulics suppliers play an essential role in today's industrial landscape. These suppliers provide crucial components that power a multitude of machines and applications, from construction equipment to automotive systems. With the increasing demand for hydraulic systems in various sectors, the expertise and product range offered by hydraulic suppliers become even more critical.

What are Hydraulics?

Hydraulics refers to the use of liquid fluid power to perform work. In simple terms, it involves the transmission of power through fluids. This technology is foundational in various industries, including automotive, aerospace, manufacturing, and construction. The main components of hydraulic systems include:

- Pumps: Generate fluid flow.

- Actuators: Convert hydraulic energy into mechanical work.

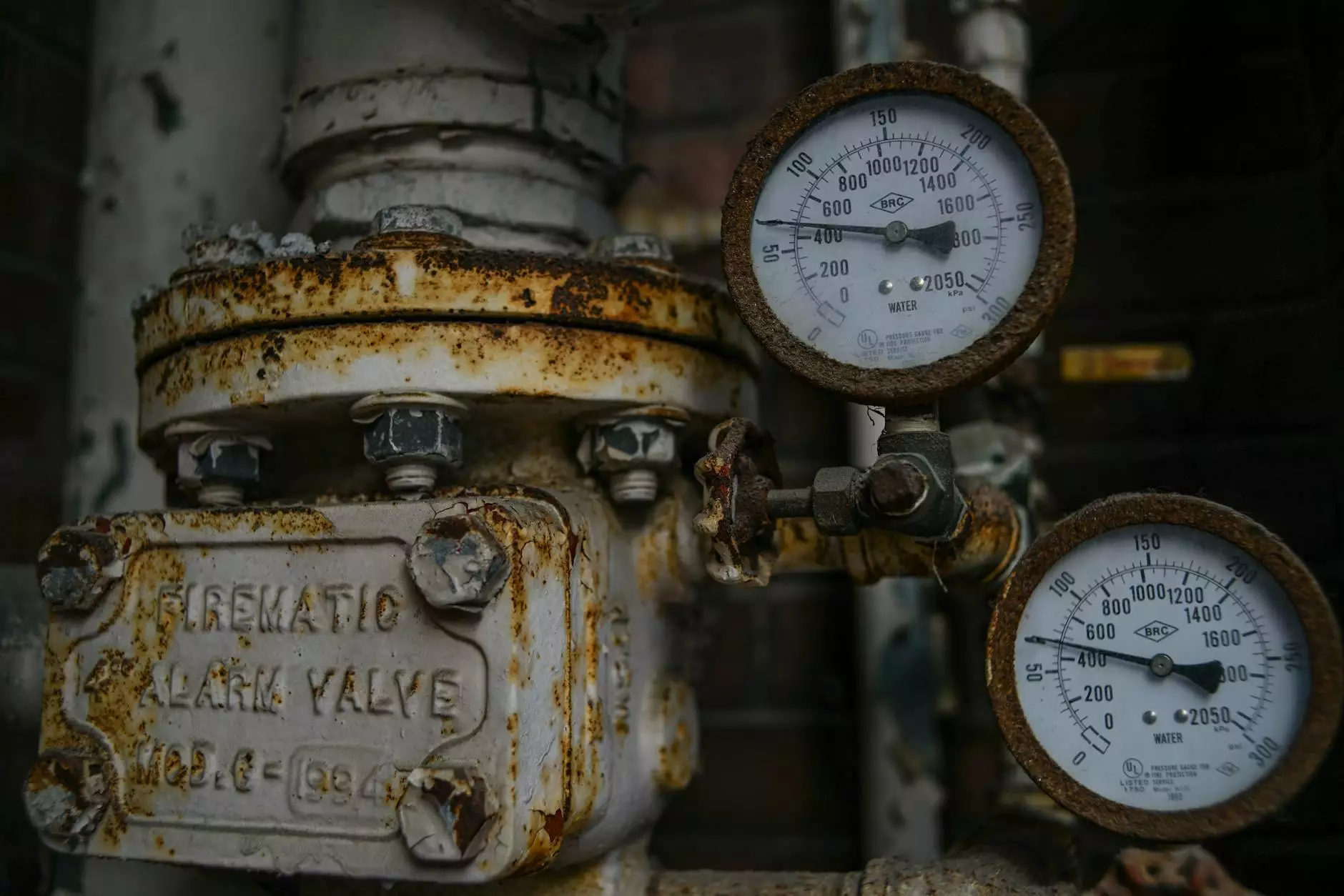

- Valves: Control the flow and pressure within the system.

- Hydraulic Fluids: Transfer energy and lubricate components.

The Importance of Choosing the Right Hydraulics Supplier

In an industry where precision and reliability are paramount, choosing the right hydraulic supplier can significantly affect your business operations. Here are several reasons why selecting a reputable supplier is vital:

1. Quality Assurance

Quality is one of the first and foremost factors to consider when selecting hydraulics suppliers. High-quality hydraulic components are critical to ensuring the efficiency and longevity of hydraulic systems. Poor-quality parts can lead to breakdowns, safety hazards, and costly downtime.

2. Expertise and Support

An experienced supplier doesn’t just sell products; they offer invaluable technical support and guidance. This expertise can assist businesses in making informed decisions about their hydraulic systems and components, ensuring optimal performance.

3. Comprehensive Product Range

Another significant advantage of working with established hydraulics suppliers is their extensive product range. A good supplier will offer a variety of hydraulic components and solutions, which can accommodate any specific needs your projects may require.

How to Choose the Right Hydraulics Supplier

Finding the best hydraulics supplier for your business involves several strategic steps. Here is a comprehensive guide to make your selection process easier:

1. Research and Recommendations

Conduct thorough research to identify potential hydraulics suppliers. Look for reviews and testimonials from other customers. Recommendations from industry peers can also provide reliable insights.

2. Assess Product Quality

Investigate the brands and manufacturers that the supplier carries. Look for certifications and standard compliance to ensure the products meet industry quality and safety standards.

3. Evaluate Customer Service

Assess how the supplier handles customer inquiries and support. Prompt and knowledgeable customer service is essential, especially during emergencies or when you need technical assistance.

4. Compare Pricing

While cost shouldn't be the only factor in your decision, it's still necessary to compare prices among different suppliers. Ensure that you are receiving good value for your investment without compromising on quality.

Applications of Hydraulic Systems

Hydraulic systems are utilized in various applications across multiple industries. Understanding these applications helps underline the importance of quality and reliability that hydraulics suppliers must offer:

1. Automotive Industry

In the automotive sector, hydraulic systems are essential for operation and control in cars, trucks, and motorcycles. These systems help in:

- Braking Systems: Provide powerful braking in vehicles.

- Transmission Systems: Assist in vehicle gear shifting.

- Power Steering: Enhances steering control and comfort.

2. Construction and Heavy Equipment

Construction relies heavily on hydraulic machinery for lifting, digging, and moving heavy materials. Equipment such as:

- Excavators: Use hydraulics for digging deep trenches.

- Dump Trucks: Utilize hydraulic systems for bed lifting.

- Cranes: Leverage hydraulic controls to lift heavy loads.

3. Industrial Machinery

Hydraulic systems are also found in various industrial machines, including:

- Press Machines: Used for metal forming and shaping processes.

- Injection Molding Machines: Essential for producing plastic components.

Innovations in Hydraulic Technology

As industries evolve, so too does hydraulic technology. Recent innovations have led to improvements in efficiency, safety, and sustainability. Here are some noteworthy advancements:

- Smart Hydraulics: IoT technology integration allows for real-time monitoring and maintenance alerts, enhancing equipment longevity.

- Bio-based Hydraulic Fluids: Environmentally friendly fluids are becoming increasingly available, reducing the ecological footprint of hydraulic systems.

- Energy-efficient Designs: New designs focus on reducing energy consumption while increasing power output.

Conclusion: The Future of Hydraulics and Its Suppliers

The future of hydraulics supplies is bright as demand continues to increase across various sectors. Reliable hydraulics suppliers like Shop Hydraulic America are crucial to ensuring that businesses operate efficiently and maintain high standards of safety and reliability. By understanding hydraulic systems and the integral role of suppliers, companies can make informed choices that lead to success.

As this industry continues to innovate and adapt, it will remain a backbone of modern machinery and technology. Businesses that invest time in choosing the right hydraulic partners will undoubtedly find themselves ahead of the curve.